x

V

I

N

S

O

N

An ISO 9001 : 2015 Certified Company

We'are Open: Sat - Thu. 9:00 AM To 7:30 PM

- Call Us

- +91 99797 95994

- Mail Us

- info@vinsoninternational.com

About Us

About Us

Vinson International is an India based leading manufacturer of Continuous Cast & Extrusion of Non Ferrous Metal Alloys. As a company with deep expertise we have always offered ground-breaking technologies, service concepts and solutions tailored to the market and true Indian quality. The company has well developed R&D team which deals with the development of new products, cost-reduction, product quality improvement, import Substitution, etc. The company is also carrying out efforts for fuller utilisation of indigenous capabilities to adopt improved method and manufacture new high value added items. R&D activities includes continuous efforts to improve the process in order to increase productivity and reduce power consumption besides development of new items of production.

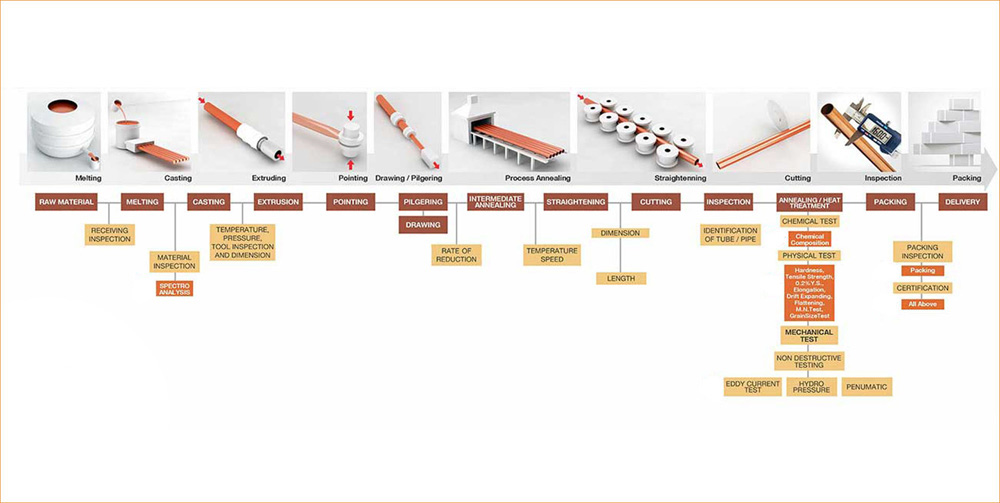

Vinson International is an ISO 9001:2015 certified company and our products meet as per ROHS and REACH compliance with ultra-modern quality control equipments and quality assurance systems using advanced equipments like Spectrometer, Eddy Current Testing, Metallurgical Microscope, Impact Testing, Conductivity Meters, Mercurous Nitrate Test, Profile Projector, LPT Test, Computerized UTM, Hardness Test, Extensometer, Ultrasonic Testing etc. We supply material in form of Rods, Wires, Hollow Rods, Sections, Flats, Ingots/Billets and Tubes as per ASTMB, BS, DIN, EN, GOST, IS, JIS, NES, EEMUA, AFNOR, DGS and all other International Specifications.

Vinson International is an ISO 9001:2015 certified company and our products meet as per ROHS and REACH compliance with ultra-modern quality control equipments and quality assurance systems using advanced equipments like Spectrometer, Eddy Current Testing, Metallurgical Microscope, Impact Testing, Conductivity Meters, Mercurous Nitrate Test, Profile Projector, LPT Test, Computerized UTM, Hardness Test, Extensometer, Ultrasonic Testing etc. We supply material in form of Rods, Wires, Hollow Rods, Sections, Flats, Ingots/Billets and Tubes as per ASTMB, BS, DIN, EN, GOST, IS, JIS, NES, EEMUA, AFNOR, DGS and all other International Specifications.

Our Vision

Our Vision is to set global benchmarks of excellence in every aspect of business. Vinson is committed to offer products and services that exactly meets or exceeds customer’s requirements and enhance their satisfaction through continual improvement and quality management system.

Our Mission

- Our Mission is to supply quality products with prompt & efficient service at competitve cost.

- Our Mission is to maintain manufacturing operations with eco-friendly solutions and minimum pollutant release.

- Our Mission is to prioritize our customers and their satisfaction with our manufacturing solutions.

- Our Mission is to create a healthy and motivated environment for our employees.

Our Values

People

Being the most crucial force behind our business, we have always endeavoured to respect and empower our people, bringing out the best in them.

Craftsmanship

At Vinson, craftsmanship is at the centre of everything we do. Paying attention to the smallest of details of the product.

Excellence

At Vinson, we are driven by an innate desire to excel in everything we do. Philosophies like ‘Get it right the first time’ and ‘Zero-defect manufacturing’ are a way of life for us.

Cutomer Success

At Vinson, we don’t merely aim to satisfy our customers but strive to help them succeed, because we believe that our customers’ success is as good as our own.

Ethics

At Vinson, uncompromising ethics are rooted in our DNA. We are committed to being transparent, fair and honest, and work with the highest level of integrity towards our people, the environment, and society at large.

Approach

At Vinson, We believe in Zero defect Manufacturing.

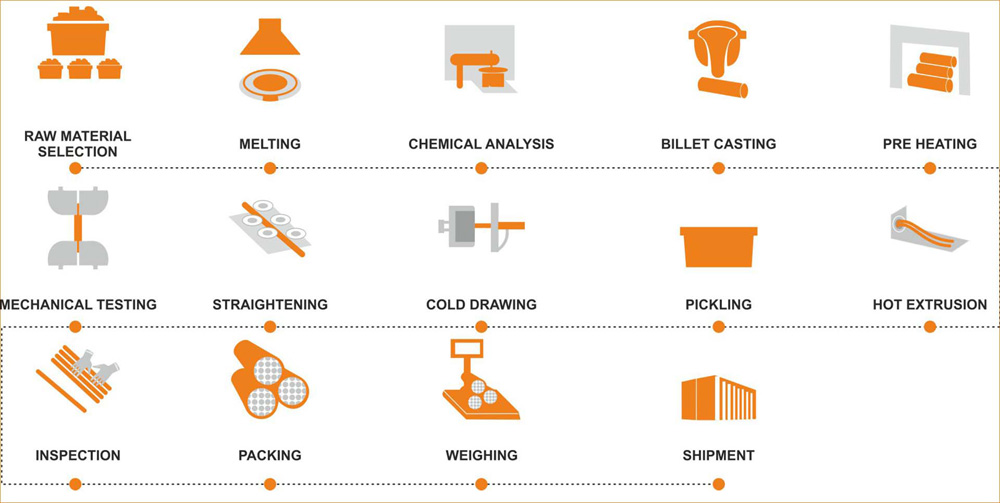

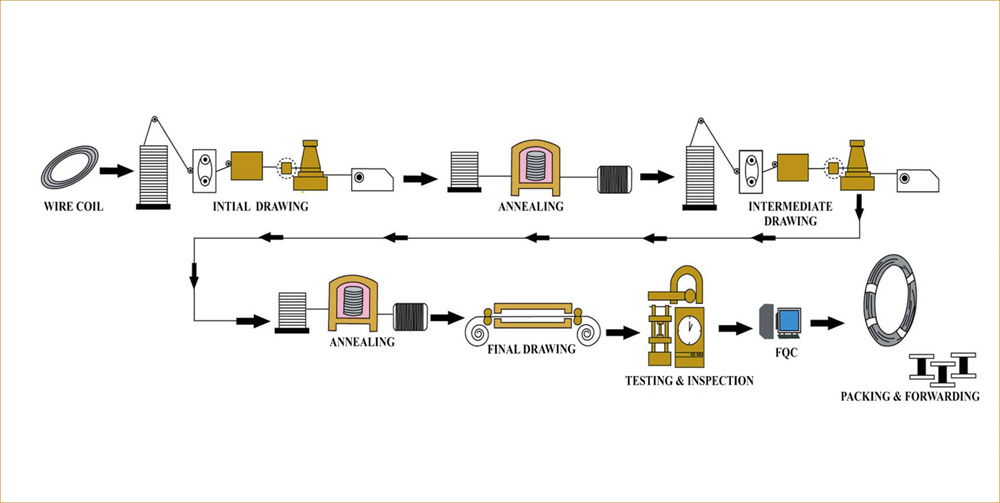

Manufacturing Process

The manufacturing process starts with best quality imported brass scrap mixed with virgin metals to ensure flexibility in meeting customer requirements. Cast Billets are subjected to test with optical emission Spectrometer to certify exact chemistry required by the customer. Extrusion of these casted billets produces defect free material in the shapes of Round, Hex, Squares, Flats and Hollow forms in pre-defined lengths. The extruded material is then pickled to prepare the surface for cold-drawing. Finishing die reduces the cross section to obtain precise tolerances. Surface finishing, straightening, machinability, physical and mechanical properties are improved through the process to meet specific customer requirements.

Infrastructure

- Establishing and maintaining a constant growth rate over the years, our ever-increasing infrastructure now consists of a state of the art production facility in Gujarat.

- Our production facility is well equipped with the latest machineries for making products in large quantities.

- One of our most valuable assets is the group of skilled engineers and workers who work in our production plant. They are the backbone of our institution and provide the most needed skills to enable us to produce superior products.

- We also take pride in our R & D team who constantly strive to bring the latest technologies to use in our products.